Ammonia Evaporative Condenser

Ammonia Evaporative Condenser

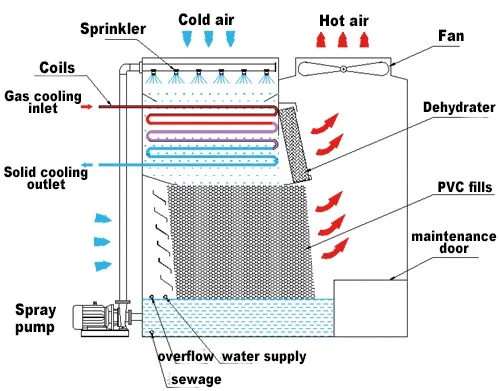

An evaporative condenser is a highly effective heat - rejection apparatus widely utilized in numerous industrial and commercial applications. This innovative device combines the power of evaporation and air - cooling to efficiently transfer heat from a hot refrigerant or process fluid. It typically consists of a casing housing a series of coils through which the hot medium flows. As the hot fluid traverses these coils, a fine mist of water is sprayed over them. Simultaneously, a powerful fan draws in outside air. The heat from the hot fluid causes the water to evaporate, and this evaporation process, which requires heat energy, significantly boosts the heat transfer rate. This makes evaporative condensers far more efficient than traditional air - cooled condensers in dissipating heat. The remaining water is then recirculated within the system. They are commonly employed in industrial refrigeration systems, large - scale HVAC installations, and power generation plants, providing a cost - effective and energy - efficient solution for heat removal and ensuring optimal performance of associated equipment.

Details

Operating Principle

MASTER COOLING evaporative condenser is a kind of highefficient heat exchange equipment renovated and developed on the basis of absorbing the most advanced heat-exchangeTechnology abroad.

MASTER COOLING evaporative condenser uses water and air as cooling agent. The cooling agent exchanges the heat with high temperature gaseous refrigerant agent and hence the refrigerant agent becomes liquid. Inside it has a water distribution system, condensing coils, wet deck, dehydrator and so on. Outside it has a water circulating pump, an electronic water curing device and a propeller fan on the top of condensing coil. The propeller fan strengthens the flow of the air and causes negative pressure inside. When the condenser runs, the cooling water is pumped and then sprayed by water distribution system on the surface of condensing coil equably to form a thin layer of water film. The high-temperature steam of refrigerer nt agent enters from the top of condensing coil and then the cooled liquid refrigerant agent is discharged from the bottom of the condensing coil. During this process, high temper ature refrigerant agent exchanges the heat with the water and air outside the coil and increases the effect of heat exchange with the help of wind. After absorbing the heat of refrigerant agent, some water turns into steam and is discharged by prop eller fan. Meanwhile, the moisture in the air is collected by dehydrator to basin, and the Ungasified cooling water flows in to wet deck and its heat is taken away by the airflow. The cooled water converges in the basin to be used circularly by the pump later. In addition, there is a ball cock in the basin. When the water is consumed to a certain point, the ball cock will automatically open to replenish the cooling Water.

Chart of Operating Principle

Characteristics of Products

Excellent Heat Exchange Performance

MST Evaporative Condensers adopt the technology of the combination of coil and stuffing to avoid the dry spot and dirty forming on the coils. So the performance of heat exchange is high effective.

Because of the same direction of airflow and water flow, the spray water can cover the surface of coils furthest and keeps the surface completely wet. Compared with the reverse direction of water flow and airflow, this structure can reduces greatly the dry spot and dirty.

Low Operating Cost and Energy Saving

Because of the unique structure, MST Evaporative Condensers have the advantages of high thermal technology performance, low condensing temperature, low water and power consumption, low noises and low maintenance cost. It is the real energy - saved and environment protected product.

Convenient Examine and Repair

With large access door and sufficient inner room, maintainers can conveniently examine and repair the equipment inside it.

Small Occupied Space and Low Whole Investment

MST Evaporative Condensers combine traditional condenser, cooling tower, circulating water pump, basin and connected pipes together. They have the advantages of small floor space and low investment.

Examine and Repair without Stopping the Operation of the Machine

The ball cock and dross filter of MST Evaporative Condensers can be examined and repaired without stopping the operation of the machine. Because of the same direction of airflow and water flow, it is very convenient to examine and repair nozzles and coils when the machine is running.

Reliable Fixing Element

The cabinets of MST Evaporative Condensers are used stainless steel (304) bolt to connect. The character inoxidability is perfect than normal. Meanwhile it assures condensing's steadily working for a long time.

Low Fault Rate

Both propeller fan and water pump adopt high quality bearing, which is the only running part that has friction. The direct

connecting structure of the propeller fan has the advantages of low transmission loss, low noise and low fault rate.

Convenient Transportation and Installation

For towers with smaller volume, integral transportation is adopted. For towers with larger volume, the standard components of the

upper and lower cabinets are transported and installed on - site, which greatly facilitates the transportation and installation of the products.

Main Components of Cooling Towers

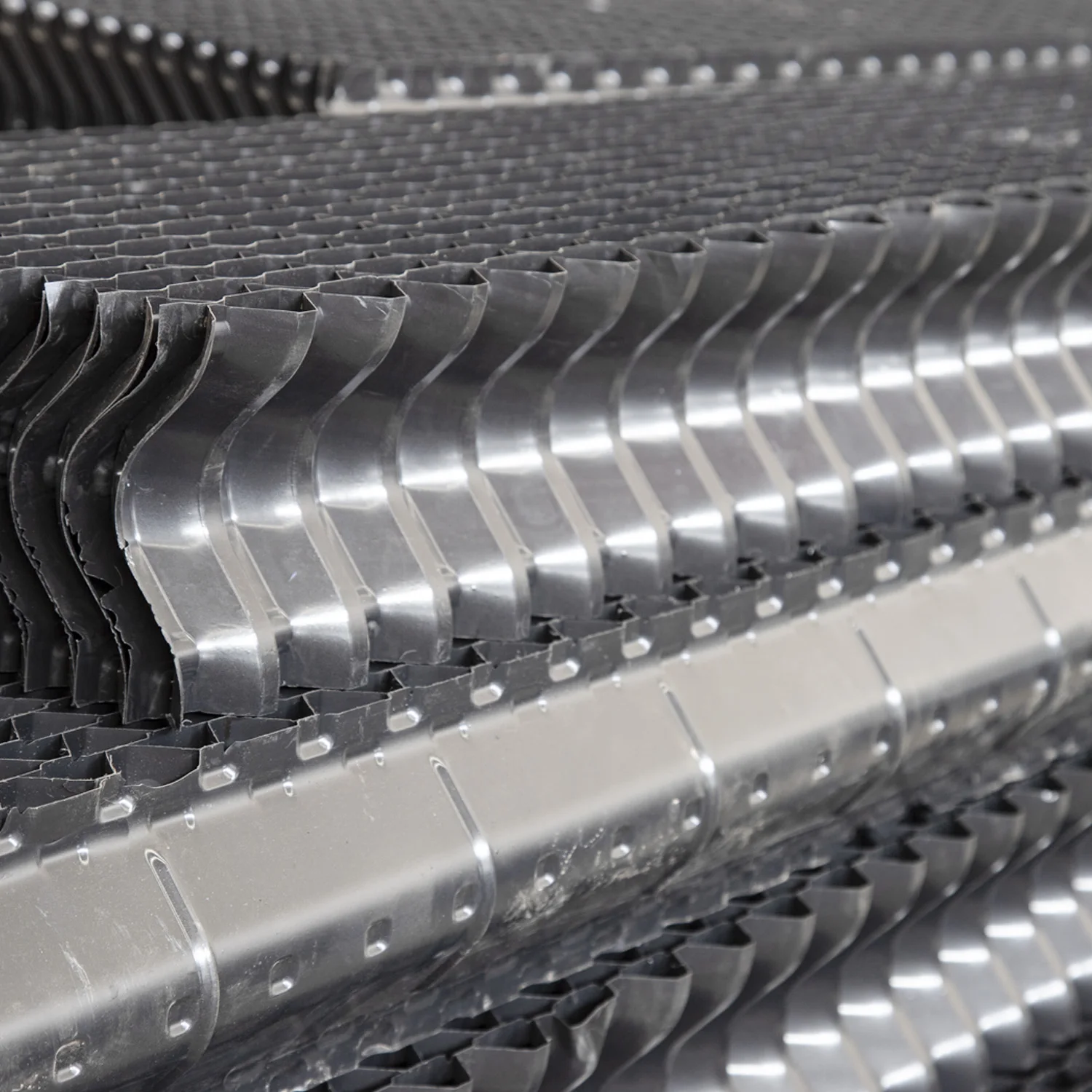

Condensing Coils

The condensing coils are made of high-quality seamless steel pipes with thickness of φ 25mm. (GB/T8163)The design pressure is 1.97 Mpa. All the coils have been pneumatically tested 3 times at 2.5Mpa to avoid leakage. The coils are galvanized to avoid being rotten. The slope of coils helps the discharge of liquid. The differential pressure of the coil is small.

Electronic Water-Curing Device (Optional Accessories)

The electronic water-curing device is very advanced and works under 220V power supply. It can help the condenser to antiscale, descale, sterilize and eliminate alga, activating the circular cooling water.

Water Circulating Pump

Circulation pump with no steering quality mechanical limit seal, no leakage, Long service life. And the special outdoor type

motor, imported bearing special configuration Card machine pump long-term reliable operation, has low power, high flow, low noise,

of Excellent performance characteristics.

Set Up Type Dehydrator

The dehydrator for MST Evaporative Condensers is made of specially designed non-corroding PVC material. The special structure can get

rid of the air moisture coming out from the coil pipe in order to change the air current 0.001%. It is very convenient to

disconnect the dehydrator when clean the raw material.

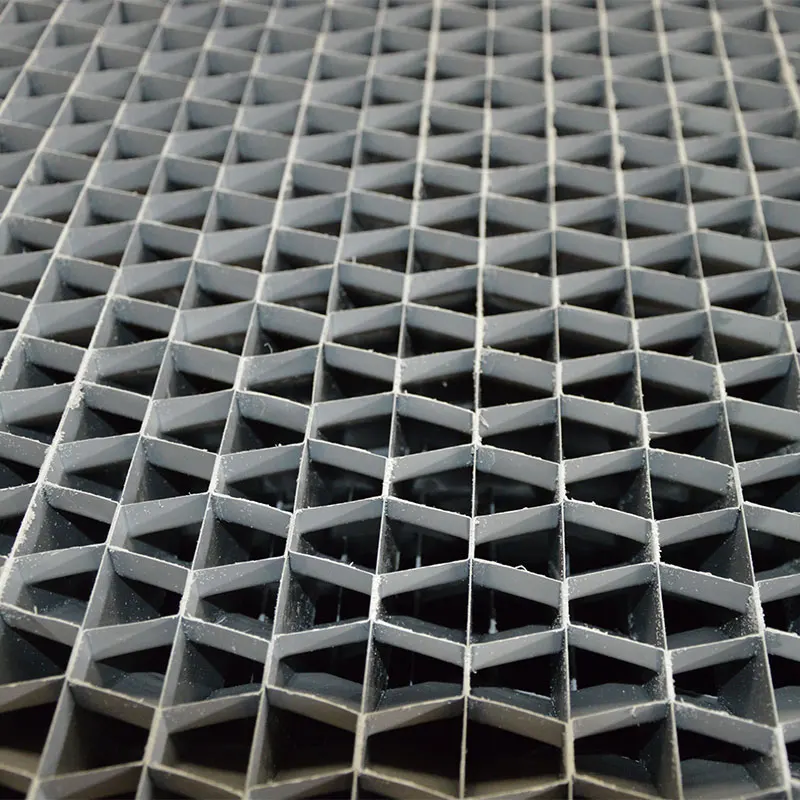

PVC Wet Deck

MST Evaporative Condensers adopt PVC honeycomb type stuffing. The short horizontal air-inlet design can help the cool air take away the heat of water immediately. Special filling pipe can make water change to float water velum. It will prolong the time of the water staying in pipe and it will have good heat exchanging effect. And it has the advantages of aging resistance, deforming resistance and low wind resistance coefficient, etc.

Propeller Fan

The ventilating system of MST Evaporative Condensers adopts the aluminum alloy propeller fan dedicated for cooling tower with high blowing rate, low damping, low noises, good performance and high efficiency. The motor is closed and self cooling. It has the advantages of small size, light weight, good start ability, reliable operation, long life time and so on.

Advanced Water Distribution System

MST Evaporative Condensers cooling water spray system adopts large discharge and anti-blockage nozzles, which can ensure the cooling water furthest contact the condensing coil and hence overcome the fouling and promote the moisture to vaporize, thus improve the effect of heat transfer. The nozzles can be easily disconnected from spray branch pipes when cleaning.

Imported board of Zinc-plate and Aluminum-plate

The outer shells of MST Evaporative Condensers are all made of Imported board of Zinc-plate and Aluminum-plate with the best stain resistance. Its lifetime is 3 to 6 times of that of the common ones. This kind of stain steel has the advantages of strong heat resistance and beautiful appearance.

Company Profile

Wuxi Master Cooling Machinery Manufacturing Co., Ltd. Founded in March 2011, is a cooling equipment overall solution provider, located in Xingshang Road, Wanshi Town, Yixing City, Jiangsu Province. We have cooling capacity test platform and testing instruments.

Our main products include: counter-flow and cross flow closed cooling tower, Stainless Steel and FRP open cooling tower, water chiller, evaporative condenser, water treatment equipment and other accessory parts. Our products are widely used in electric power, chemical industrial, metallurgy, cooling, light industrial, civil facilities and other fields.

Certifications

Why Choose Us

(1)We have complete service of cooling tower equipment

(2)We can provide the perfect water treatment solutions and cooling system

(3)We provide OEM/OEM service

(4)Can you see the running machine in our factory?

Yes. Before making your decision ,you can test-run the equipment in our factory

(5)How long of the warranty time?

Our warranty period is 1 year.

(6)We have a strong after-sales team and technical solutions, we can provide you with a full range of solution applications.